|

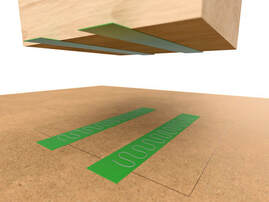

I use a CA glue a lot in my woodshop. It has many applications with so much of my things I use. It's perfect for use on 3d printed parts. When doing a model, sometimes I make models and split them in half to save from printing. Ca glue is perfect for this application as it only takes several seconds to fully dry. Even faster with the accelerant! It's also perfect for laser projects. One of the things you'll inevitably make is a name sign or door hanger. This usually requires cutting a shape like a circle as the backer, then cutting some cursive letters. Starbond is the glue I use to adhere the letters to the backer. It has no problem gluing to painted surfaces. The last, and probobly most used case for CA glue in my shop is on my CNC machine. It's something called the 'blue tape method'. Basically, the idea is to put on piece of painters tape on the underside of the material you're going to cut, and another onto the wasteboard. Then, put some ca glue between the two pieces of tape, a ca glue sandwich if you will, to create a perfectly heled piece that will will stay put during carving and be easily removable when it's finished. It also means there's not clamps or bolts that can be in the way of the endmill. Use Code 'myerswoodshop' at checkout to |

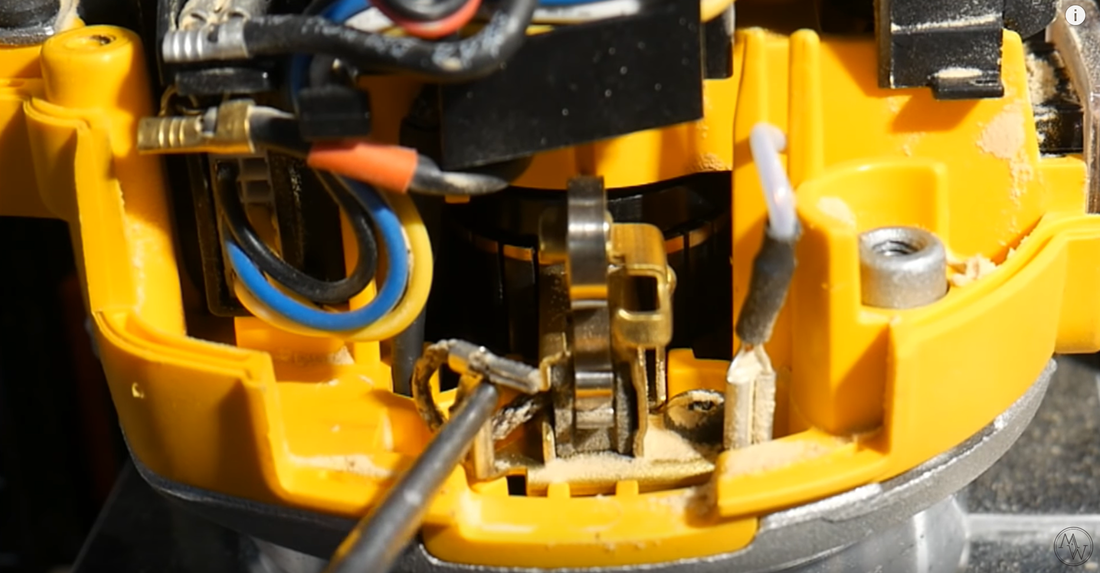

What i do is have this camera set up so I can periodically check in and make sure everything is cutting fine. In the event of a catastrophic error, I pair the camera with a wifi outlet. I have my CNC and Router plugged in to the wifi outlet and can shut if off anywhere I have internet or cell reception.

Click the two links on the right to buy the same products I use. It's a small price to pay for piece of mind.

|

|

|

Happy Making!

-Ben

Categories

All

3D Printing

CNC

Deals

Featured Makers

Fiber Laser

Laser

Onefinity

Patreon

Podcast

Shipping

Shop Tour

The Build Guild Podcast

Tools

T-Shirts

Tundra

VR

Woodworking Projects

Archives

November 2023

June 2023

November 2022

August 2022

January 2022

November 2021

October 2021

March 2021

February 2021

January 2021

December 2020

November 2020

October 2020

September 2020

July 2020

June 2020

May 2020

April 2020

March 2020

February 2020

January 2020

November 2019

October 2019

September 2019

August 2019

July 2019

June 2019

May 2019

April 2019

March 2019

February 2019

January 2019

December 2018

October 2018

September 2018

August 2018

RSS Feed

RSS Feed