Unleashing Your CNC Creativity: The Power of CARVECO Software with Onefinity, Shapeoko, and X-Carve11/15/2023 In the exciting world of CNC machining, hobbyists are constantly seeking ways to elevate their craft. Whether you're a seasoned enthusiast or just starting out with a CNC machine like Onefinity, Shapeoko, or X-Carve, the right software can make all the difference. Enter CARVECO, a versatile and powerful design and carving software that caters to the needs of hobbyists and professionals alike. In this blog post, we'll delve into why CARVECO is an excellent choice for users of hobby CNC machines, exploring its pros and cons and shedding light on the investment required. Pros of Using CARVECO with Hobby CNC Machines:

Use code

|

|||||||||||||||

| draw_1f.zip | |

| File Size: | 658 kb |

| File Type: | zip |

Check out the 'how to install' a Lightburn material library below also!

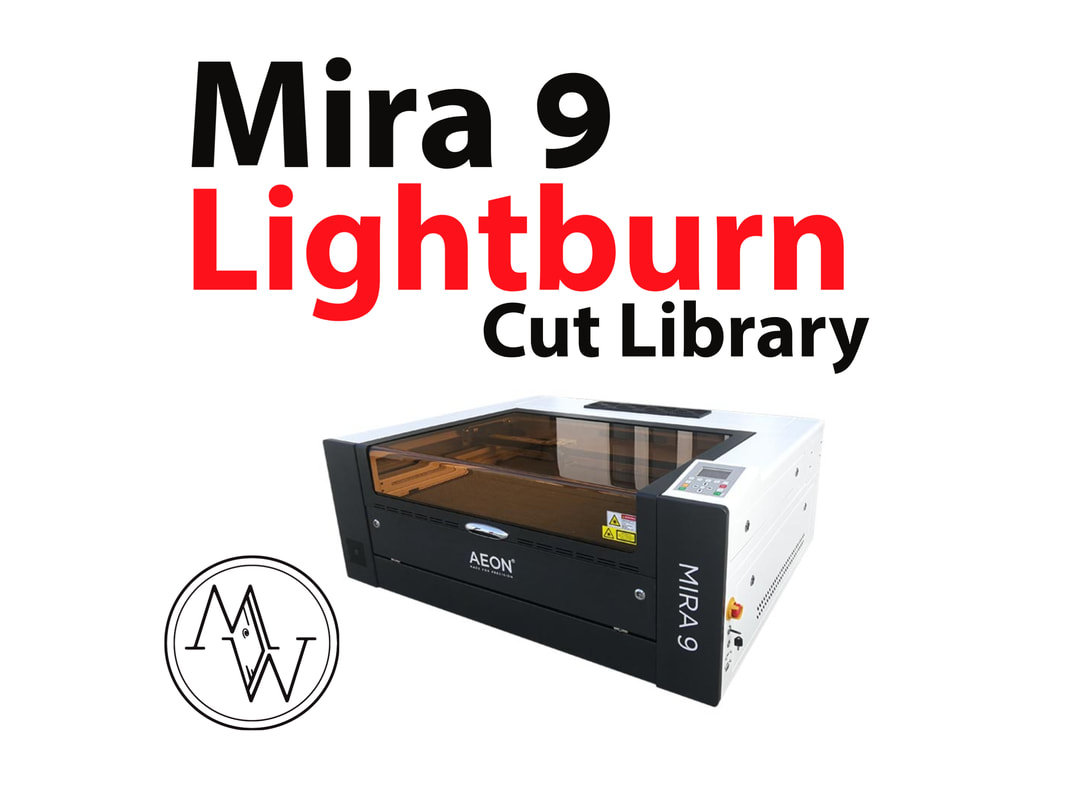

Etsy Links To Different Material Libraries (click the picture to get them):

TOOLS / MATERIALS

■ Camera Bracket : https://www.etsy.com/listing/1267508521/2022-tundra-bracket-trd-pro-heritage

■ Dewalt Electric Ratchet : https://amzn.to/3SSrXtq

■ 2022 Toyota TRD Pro Grille - Part # 53101-0C220 : https://parts.toyotaofgrandrapids.com/oem-parts/toyota-grille-sub-assembly-rad-531010c220

■ Plastic Car Pullers : https://amzn.to/3pj6c8o

Buy the Camera Bracket here:

How to install video:

Referral Code for FREE GAMES!

https://www.oculus.com/referrals/link/MyersWoodshop/

Perform a factory reset:

1. Turn off your headset.

2. Hold the power and volume (-) button on your headset down simultaneously until the boot screen loads on your headset.

3. Use the volume buttons on your headset to highlight Factory Reset and press the power button.

4. Use the volume buttons on your headset to highlight Yes and press the power button.

Once you've gotten to this step, try using the above referral code again. Once accepted, you can now turn on your Oculus Quest and set it up like normal, this time, with credit for FREE games!

This allows you to take the guess work out of finding the right settings for your Mira 9! No more wondering what speeds and power, dpi, etc. to start with!

Follow me on YouTube: https://www.youtube.com/myerswoodshop for laser video how tos and projects!

This is an instant digital download! You must 'load' the file iin the 'library' tab of Lightburn.

Has the following materials:

Acrylic

Birch Plywood

Cardboard

Doormat

Hardboard

Leather

MDF

Oak

Yeti Powder Coat

LightBurn's Material Library provides a way to store and organize lots of presets for different operations on different materials, and have a way to quickly apply them. This is entirely user-generated - You set up a cut layer however you like and save it to a Library. You set a material type, thickness (if appropriate), and a short description.

Every file in one place. |

This file now includes premade Vectric files as well! It also includes EVERY size wasteboard! No matter what size Shapeoko, Onefinity, Xcarve, millright, oozenest, shark, cnc4newbies or others, this will have a size that will fit your hobby cnc!

For use on ALL hobby CNC machines including: Shapeoko, Onefinity, XCarve, Millright, Oozenest, CNC4Newbies, Shark, and many more!

These file types for each item include:

.crv (vectric, paid) design files (includes shapes AND toolpath information). Ready to run, just click 'create gcode' (with the proper post processor for your machine) and cut!

.c2d (carbide create, free) design files (includes shapes AND toolpath information). Ready to run, just click 'create gcode' (with the proper post processor for your machine) and cut!

.svg (vector images (shapes only, do not carry toolpath info) (for use with all other CAD design software)

.dfx (vector images (shapes only, do not carry toolpath info) (for use with all other CAD design software)

Includes:

Wasteboard: 16x16, 24x24, 31x16, 31x31, 48x32

Flattening: 16x16, 31x16, 31x31, 48x32

Fence: 16x16, 31x16, 31x31, 48x32

Cam Clamps

Corner Clamps

Straight Clamps

L Clamps

Please check out these videos for help with creating and understanding the differences between file types

1) https://www.youtube.com/watch?v=6OoMsJezGUc (wasteboard)

2) https://www.youtube.com/watch?v=RdoqXafKOW0 (fence)

3) https://www.youtube.com/watch?v=0GKKOPvAH60 (common mistakes on CNC)

4) https://www.youtube.com/myerswoodshop

I've put together an ever evolving Amazon list of CNC stuff I think is useful or necessary here:

https://www.amazon.com/shop/myerswoodshop

Want to support my work (like the upcoming V2 of the wasteboard?)

Consider Supporting me on Patreon:

https://www.patreon.com/myerswoodshop

Listen to my Podcast (the build guild podcast) here:

www.thebuildguildpodcast.com

Find me on the internet:

www.myerswoodshop.com

www.youtube.com/myerswoodshop

www.instagram.com/myerswoodshop

www.facebook.com/myerswoodshop

www.facebook.com/MyersWoodshop/groups/

www.tiktok.com/myerswoodshop

Files created by:

Vectric 11

Carbide Create V620

Last Updated 10/12/2021

Copyright Myers Woodshop 2021

| If you're like me, you sell goods online and ship around the world. I sell quite a bit of my woodworking tools on my Etsy shop. I used to print every label on my inject printer. It would take forever to print one page and I constantly felt like I was buying more ink than I was using. That quickly changed once I found this little thermal label printer! |

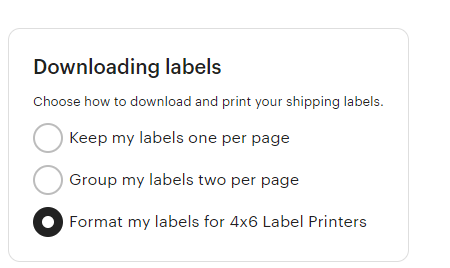

| Since I manly ship on Etsy, it was very easy to setup. Once I installed the driver, simply go into Etsy shop manager, settings, shipping settings, and look under Shipping label preferences. There is a section that says 'downloading labels'. Simply choose, "format my labels for 4x6 label printers' and your set up! Easy as pie. |

| Another bonus of the thermal printer is the cost per label. I purchased the thermal roll (click picture to the right to purchase) and it will do 220 labels for around $10. Since there is no ink, it's much more economical than traditional inkjet printers and the cost of paper, ink, and tape to apply the label. The rolls are basically a sticker, so just peel off and apply it to your shipping package. MUNBYN 4"x6" Direct Thermal Shipping Label Compatible with Dymo Labelwriter 4XL 1744907,1755120, Perforated Postage Label Paper for MUNBYN, Dymo, Rollo, Zebra, Permanent Adhesive, 220 Labels/Roll |

Here is the Munbyn ITPP941 Thermal Printer Driver:

*I'll be updating this post in the future with MUCH more info. For now, enjoy the video!*

Categories

All

3D Printing

CNC

Deals

Featured Makers

Fiber Laser

Laser

Onefinity

Patreon

Podcast

Shipping

Shop Tour

The Build Guild Podcast

Tools

T-Shirts

Tundra

VR

Woodworking Projects

Archives

November 2023

June 2023

November 2022

August 2022

January 2022

November 2021

October 2021

March 2021

February 2021

January 2021

December 2020

November 2020

October 2020

September 2020

July 2020

June 2020

May 2020

April 2020

March 2020

February 2020

January 2020

November 2019

October 2019

September 2019

August 2019

July 2019

June 2019

May 2019

April 2019

March 2019

February 2019

January 2019

December 2018

October 2018

September 2018

August 2018

RSS Feed

RSS Feed