|

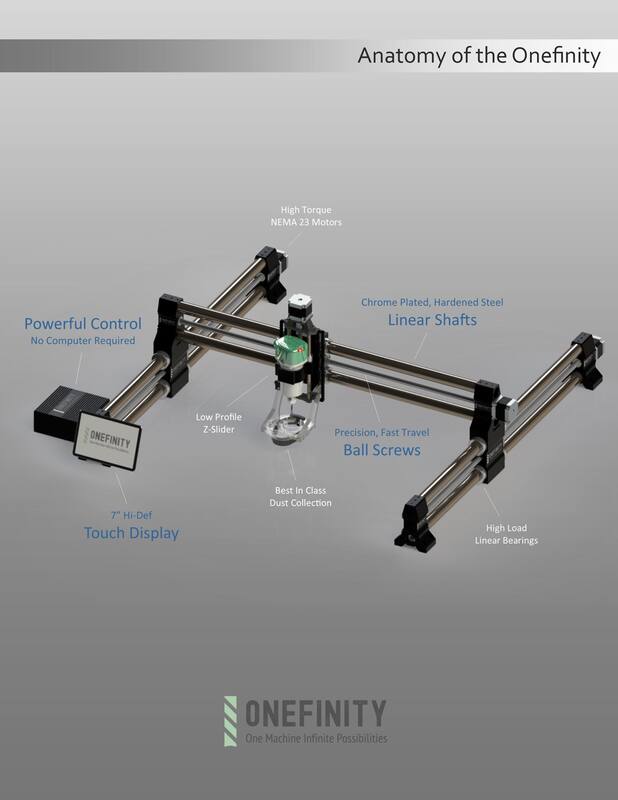

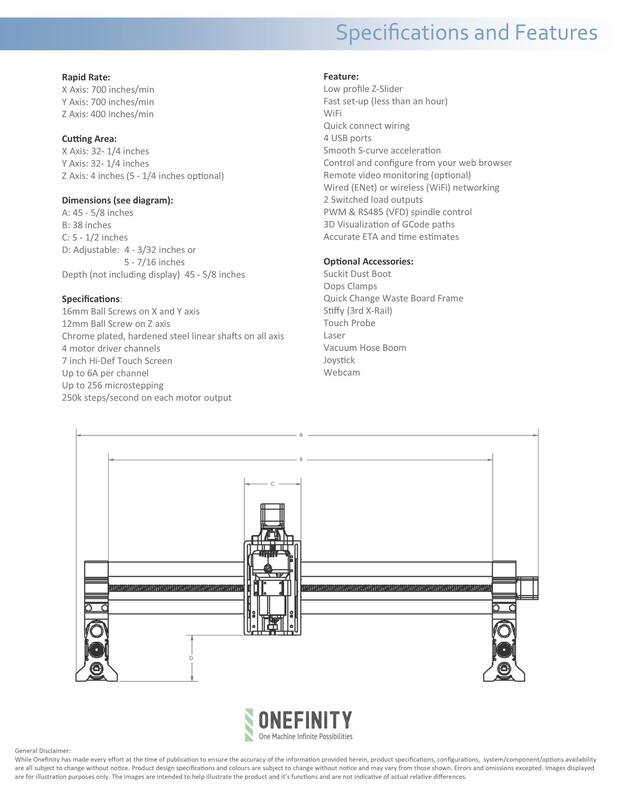

' I'm happy to say I have the Onefinity CNC in my shop! Made by the people behind Suck It dust boot, it's an all axis ball screw machine in a modular design that only took me less than 15 minutes to breakdown in my shop and move, set up and cut in my friends shop. Remember when you put together the Carbide 3D Shapeoko and it took a full day...or worse, the Inventables X-Carve and it took 5 FULL DAYS! From unboxing to cutting you'll be done in less than an hour (it took me 15 minutes). Moving the other machines takes two people. You can move and set up this one by yourself. The beauty of this machine is when you want to move it, you can move one rail at a time. You don't need a truck or large suv to move the Onefinity. I took it over to my friends shop in my wifes car. I'm a huge tech nerd so anytime you put wifi in something I'm all in. The controller is something special. It's basically a computer inside. Gone are the days where I have to hook up a usb cord from my computer to the controller on my cnc machine and tie it up until the piece is finish, or worry that my computer or usb might go to sleep in the middle of the cut and I lose hours of work. Also, who want's to take their expensive laptop in the shop to get dusty or drop it? Once you have your design done and you save the gcode file, you simply put it on a usb stick or log into the controller via your network (if you choose to do this, wifi/internet is NOT a requirement for it to run) and transfer the file. Simply zero your work piece via the touch screen and click start. If you've used cncjs or ugs you'll love the feature that shows the simulation of tool paths while it's cutting. The Onefinity has that feature built in as well. You can monitor your cut and it's movements while it's cutting. That's really handy when you're trying to avoid cutting into your clamps. The awesome part of optionally connecting it to your network is the ability to use your phone (or tablet) to control the machine! I always have my phone on me and love the fact I can control it from wherever I am. If you hook up a usb webcam (any of the shelf usb webcam will work) a screen will show on the controller page of the camera's view. You can watch your machine cut directly from the screen! This is perfect for those long jobs when you want to head back in the house to catch an episode of Tiger King on Netflix but still want to monitor your cnc for any 'mishaps' that may happen. You basically created your own cnc baby monitor. The controller also has hook ups for VFD (for when you want to graduate from a trim router to a spindle) built right in. I have a usb gamepad controller hooked into mine for when I want to jog the machine while not directly in front of a screen. Almost too many options for jogging and control. There's a larger z height than I'm used to on this machine which allows me to cut thicker stock. And if I raise up the rails I can put as thick of a stock as I'd like underneath. I could even potentially place it on top of a completed table and carve in a design. That's a huge up sell if your created custom furniture. The Linear bearings are sealed so there's no need to worry about dust entering them. I constantly had to clean my v wheels and the rails that they road on to keep them smooth before. Ever have a belt snap in the middle of a paid job or a rubber v wheel break in half? You either have to start all over or wait to get a new belt or v wheel from amazon. With ball screws that problem goes away. As for maintenance, after a certain amount of hours on the machine, simply apply oil in the ball screw hole and that's it. I've seen way to many complain about making my wasteboard and it not drilling the holes all the way through. 99% of the time the problem was the stepper motors skipping steps because the belt was loose. Belt stretch is real. When you get your new machine or new belt you account and adjust for the belt. After time rubber will loose its elasticity and stretch. This will cause your circle to come out ovals. Ball screws eliminate that problem too. Since the controller has built in cam, you'll just need to provide your own CAD program that can create files. I've tried Carbide Create, Easel, Fusion 360, Meshcam, Solidworks and Vetric Aspire (Vetric is my go to) so far. All work just fine. I intend to try out Carveco soon. It's highly likely that those will cover 90% of the users out there. Basically, If your CAD program creates gcode, you'll more than likely be able to run it one the Onefinity. The Onefinity uses the proven nema 23 motors just like the xcarve and shapeoko 3 does. Rapid movements are increased up to 700 inches/minute on x and y and 400 on the z. Bottom line, it's pretty fast for a hobby CNC. Faster than what I'm used to. I've been using the machine for a couple of months now and I've had zero issues thus far with rigidity. The rails have been doing a great job keeping things rigid. I'm cutting at faster IPM's than I have thus far. I could basically use the rails as a pull up bar and there wouldn't be flex. Overall, I think the Onefinity is a great addition to the hobby / desktop cnc scene. It offers the higher priced machine features that more expensive machines carry at an affordable price (which I EXPECT to be priced in the same ball park with xcarve and shapeoko. We will find out for certain in May 2020). Check out the videos below to see more of the Onefinity in action. Hit me up with any questions or comments. Happy Cutting, -Ben Find Onefinity at their website www.onefinitycnc.com Also, follow them on social media: Below are the specifications of the machine:

The following are some YouTube Videos of the Onefinity CNC machine.

10 Comments

|

Categories

All

“As an Amazon Associate I earn from qualifying purchases.”

Archives

November 2023

|

RSS Feed

RSS Feed